Your dieline is the heart of your packaging design. Learning the basics of dieline creation will guarantee that your project doesn’t sink before it sets sail. This article you will learn all about dieline packaging from what it is, the packaging dieline templates options available, and the biggest mistakes brands and designers make.

Why are Dielines Important?

Dielines are a fundamental part of product packaging design. In fact, most designers won’t start a project until they have a dieline on hand. It’s in your best interest to understand what goes into each dieline and how to make the dieline creation process as straightforward as possible.

What is a Dieline in Packaging?

In the simplest terms, dielines are digital files of packaging templates that give designers all the information they need to create a finished product. Think of dielines as the blueprints that ensure proper layout for a printed product:

- Package dimensions, sizing, and scale

- Location of visual elements, such as images, logos, and text

- Placement of folds, creases, glue tabs, cut lines, eye marks, and other connection points

- Bleed requirements and any other unique manufacturing notes

Dielines are required for every printing project, from the most basic packaging to custom packaging that is one of a kind. We can categorize dielines into three departments which are the box dieline, bag dieline, and label dieline.

Dielines lay out these elements to give designers a comprehensive view of how packaging will look after printing. For an easy visualization of this process, go into your kitchen and grab a box of crackers or cereal. Unfold the tabs and lay the box out completely flat on the table. You can easily see the folds and creases as well as how the visual elements work in coordination with one another on the box’s front, back, and sides.

Who Creates The Packaging Dieline?

While the graphic designer can create the artwork, the dieline is most often created by the packaging design agency or the packaging printer. These are the experts who can ensure a proper layout for printing. The strategy, however, involves anyone within the creative team who is responsible for the product launch.

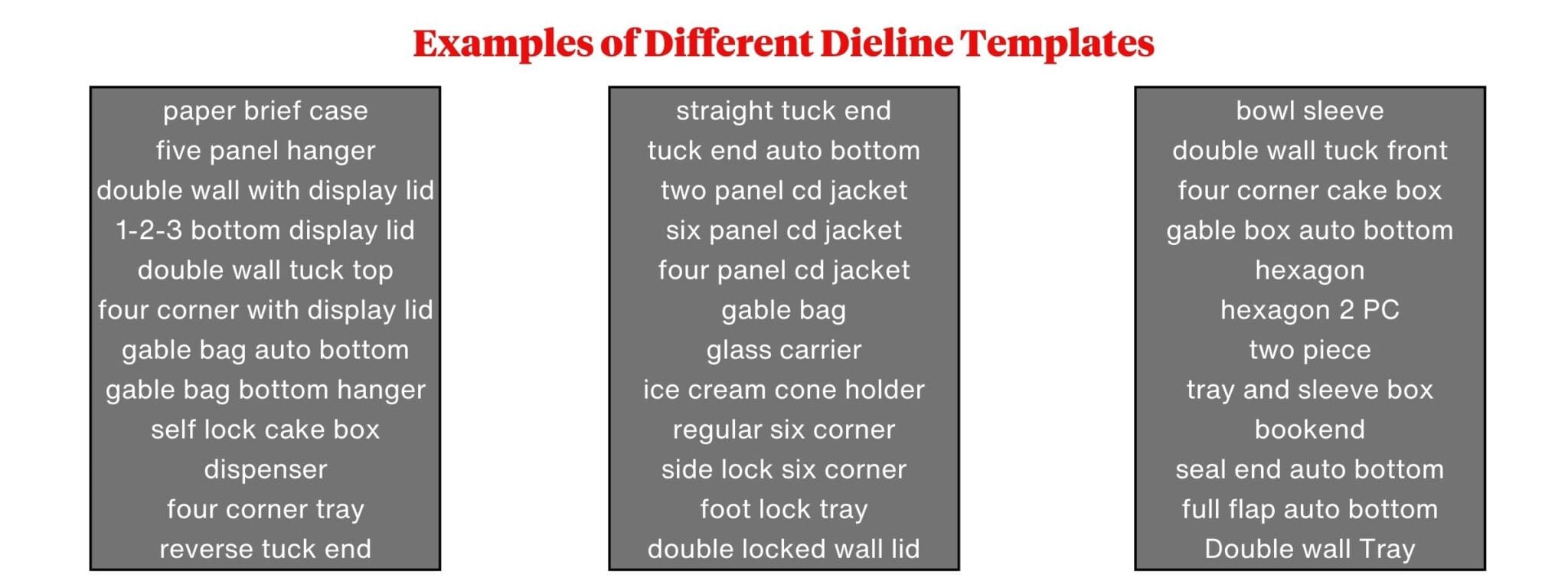

What Types of Packaging Dielines Are there?

Because of the diversity of product sizes in CPG categories, there are a wide variety of dieline types for food packaging, beverage packaging, nutraceutical packaging, and other broad markets. The shape and type may differ, but they will all include a fold line, cut line, and the other traditional aspects of a dieline.

Here’s a list of dieline examples

Each of these dieline templates act as a starting point for your finished design. They provide the framework that lets your designer and creative team create a stunning look and interesting message that looks good once printed.

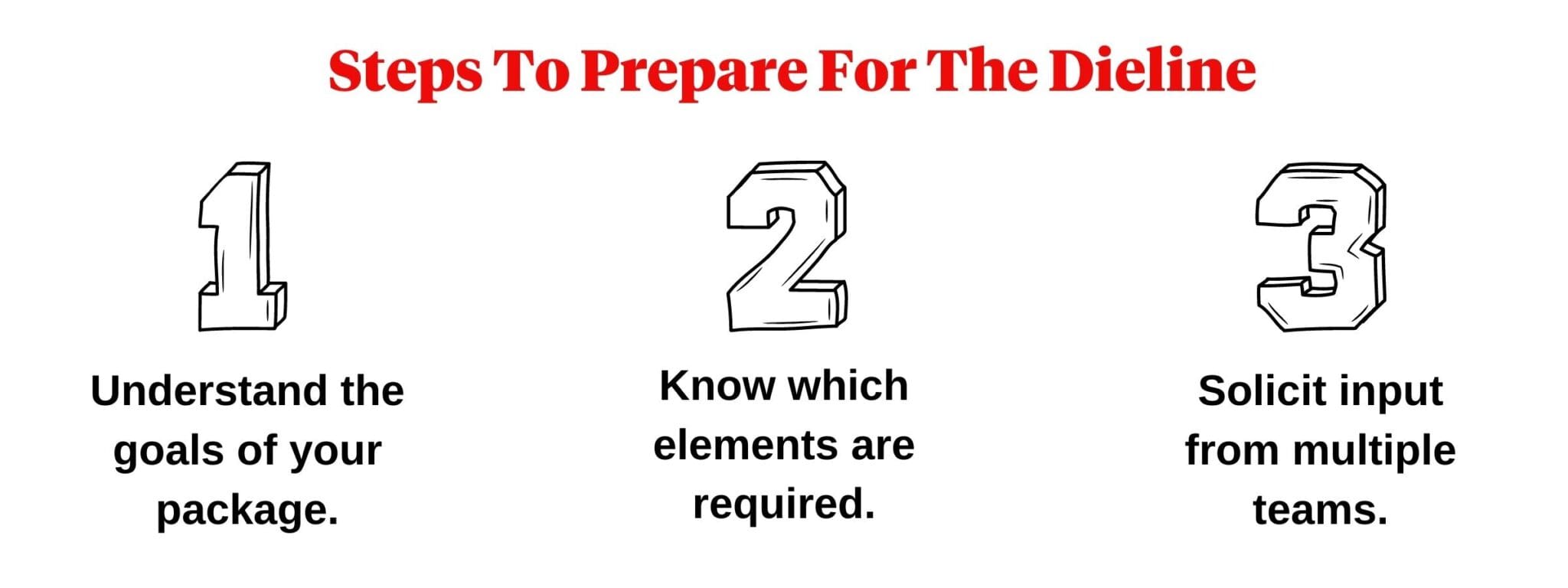

Prepare for Dieline Creation

Given that fluctuations as small as a sixteenth of an inch in package design can require a reworking of your project, accurate dielines are necessary from the start. And while package design teams handle the fine details of package deconstruction, measurement, and production, product sellers need to prepare for these meetings ahead of time:

1. Understand the goals of your package: What should your package accomplish? Which visual elements are most important? Is your product better served by striking visual imagery or with descriptive lists of your value propositions? Your designer won’t be able to answer these questions for you, so make sure you understand these concepts before the drafting process begins.

2. Know which elements are required: Depending on your product, your package will need to include specific elements as mandated by law. For example, all food products require FDA-approved nutrition panels, while cleaning products and other chemicals will require safety warnings within the labels.

3. Solicit input from multiple teams: Dieline creation is just one step toward your overall packaging production. Depending on whether you’re starting from scratch or working from a template, you may need the input of additional experts. These experts may include structural designers, who provide guidance on how stable and functional different packaging options may be.

That last point is critical. Your dieline will be a collaborative effort among you, your design team, and any other outside experts that may be required for your particular project. You should involve your creative teams early in the packaging creation process. Nothing is worse than spending weeks working on a design only to be told that the material you chose is inadequate, requiring you to start from scratch.

Remember, the dieline is the foundation for your design-take your time with the process.

Steps to Creating a Dieline

The amount of steps is consistent among all dielines, but the amount of revisions may require the steps to be taken again.

- Dieline Rough Draft: In this step, you create several design concepts using the correct dieline template.

- Dieline Revision: After choosing your final design, you will want to look at your dieline packaging in its flattened form, as a mockup, and in real life. Multiple revisions may be required.

- Dieline final draft: Only after you’ve gone through the previous steps is it time to submit your dieline to the packaging printer. There still may be some follow-up questions by the packaging manufacturer, so the reality is a final dieline only exists once the packaging has gone to print.

Common Dieline Mistakes

We reached out to dieline printing expert Jimmy Tsai from K1 packaging for what he felt were the most common dieline mistakes that brands and designers make.

- A lack of communication: We find problems occur anytime an independent designer creates their own dieline without confirmation from the manufacturer. Communication is necessary to determine if the dieline fits the machine and sizing requirements. There need to be checks and balances throughout the entire design and package printing process.

- Inaccurate Spec Sheets: Specific to labels, bottle manufacturers often have their own spec sheets that do not accurately depict the curvature of the product. The result is a label that is vertically too large, resulting in a label that is not fully applied to the bottle. We should always remeasure the curvature beginning and end points when printing dielines.

- Material durability: While it might not seem applicable to the dieline, errors occur in a finished product do not account for the finished good. We need to test the packaging based on the product weight, ingredients, shipping experience, and the duration of time on the shelf. Functionality needs to be considered in addition to design aesthetics.

To prevent these mistakes and determine the correct layout, the brand, designer, and manufacturer all need to sign off on the finished dieline. Complete this step after sending mockups and sample packaging to each party with matching product weight contained inside.

What to do if you make a mistake?

Hopefully, by reading this article you’ll avoid the painful experience of fixing a dieline mistake. But if this happens, you are bound to experience time delays and added costs.

If you experience a dieline mistake, reach a mutual agreement with the manufacturer. As k them to expedite the reprinting and only add the time and materials cost to the second bill.

Packaging Design Agency: From Strategy To Print

SmashBrand is a packaging design agency helping CPG brands win on-shelf. Our team takes care of the entire packaging process from the dieline design to package performance testing. Book a time to discuss your project with our team.

Subscribe to

Nice Package.

A monthly newsletter that unpacks a critical topic in the FMCG & CPG industry.

Free Resource.

CPG product repositioning guide.

Explore the five undeniable signs your CPG product needs repositioning along with strategies for leveraging consumer insights for a guaranteed market lift.

Learn More About CPG product repositioning guide.